| Brand Name: | Retek |

| Model Number: | W8520A |

| MOQ: | 1000pcs |

| Price: | Negotiable |

| Delivery Time: | 14days |

Blower Heating Brushless DC Motor-W8520A

A blower heating motor is a component of a heating system that is responsible for driving the airflow through the ductwork to distribute warm air throughout a space. It is typically found in furnaces, heat pumps, or air conditioning units.The blower heating motor consists of a motor, fan blades, and housing. When the heating system is activated, the motor starts and spins the fan blades, creating a suction force that draws air into the system. The air is then heated by the heating element or heat exchanger and pushed out through the ductwork to warm the desired area.

It is durable for harsh vibration working condition with S1 working duty, stainless steel shaft, and anodizing surface treatment with 1000 hours long life requirement requirements.

PRODUCT DETAILS

Product introduction

The blower heating motor has the following characteristics: The blower's rotor is carefully balanced to ensure smooth operation and minimal vibration. It operates at a higher speed, resulting in smaller gaps between the rotor and the body, reducing leakage and increasing volume efficiency.The impeller runs frictionless, eliminating the need for lubrication and producing oil-free discharged gas, this makes it suitable for applications in the chemical and food industries.The blower operates based on volume, with relatively little change in flow rate with varying pressure. However, the flow rate can be adjusted by changing the speed, allowing for a wide range of pressure options and flow control. Its structure is designed to minimize mechanical friction loss, only the bearing and gear pair have mechanical contact, and the rotor, housing, and gear ring have sufficient strength. This design ensures safe operation and a long service life.

These technical requirements help ensure optimal performance of the blower heating motor, providing efficient and consistent airflow for heating purposes.

General Specification:

Application:

Vacuum cleaner, Air conditioning, Exhaust system and ect.

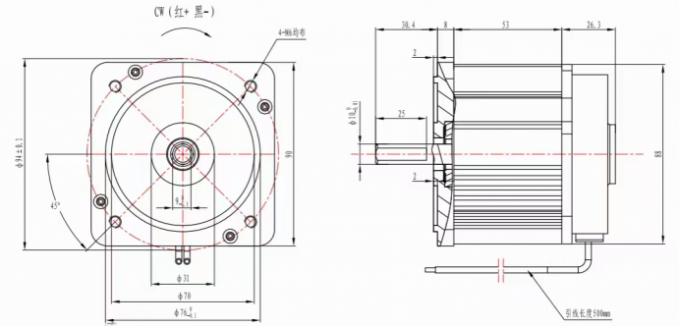

Dimension:

Parameters

| Items | Unit | Model |

| W8520A | ||

| Rated voltage | V | 74(DC) |

| No-load speed | RPM | / |

| No-load current | A | / |

| Rated speed | RPM | 2000 |

| Rated current | A | 2.5 |

| Rated power | W | 120 |

| Rated Torque | Nm | 0.573 |

| Insulating Strength | VAC | 1500 |

| Insulation Class | F | |

| IP Class | IP40 |

FAQ

1. What are your prices?

Our prices are subject to specification depending on technical requirements. We will make offer we clearly understand your working condition and technical requirements.

2.Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity. Normally 1000PCS, however we also accept the custom made order with smaller quantity with higher expense.

3.Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

4.What is the average lead time?

For samples, the lead time is about 14 days. For mass production, the lead time is 30~45 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

5.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal: 30% deposit in advance, 70% balance before shipment.

| Brand Name: | Retek |

| Model Number: | W8520A |

| MOQ: | 1000pcs |

| Price: | Negotiable |

| Packaging Details: | 15PCS/Carton |

Blower Heating Brushless DC Motor-W8520A

A blower heating motor is a component of a heating system that is responsible for driving the airflow through the ductwork to distribute warm air throughout a space. It is typically found in furnaces, heat pumps, or air conditioning units.The blower heating motor consists of a motor, fan blades, and housing. When the heating system is activated, the motor starts and spins the fan blades, creating a suction force that draws air into the system. The air is then heated by the heating element or heat exchanger and pushed out through the ductwork to warm the desired area.

It is durable for harsh vibration working condition with S1 working duty, stainless steel shaft, and anodizing surface treatment with 1000 hours long life requirement requirements.

PRODUCT DETAILS

Product introduction

The blower heating motor has the following characteristics: The blower's rotor is carefully balanced to ensure smooth operation and minimal vibration. It operates at a higher speed, resulting in smaller gaps between the rotor and the body, reducing leakage and increasing volume efficiency.The impeller runs frictionless, eliminating the need for lubrication and producing oil-free discharged gas, this makes it suitable for applications in the chemical and food industries.The blower operates based on volume, with relatively little change in flow rate with varying pressure. However, the flow rate can be adjusted by changing the speed, allowing for a wide range of pressure options and flow control. Its structure is designed to minimize mechanical friction loss, only the bearing and gear pair have mechanical contact, and the rotor, housing, and gear ring have sufficient strength. This design ensures safe operation and a long service life.

These technical requirements help ensure optimal performance of the blower heating motor, providing efficient and consistent airflow for heating purposes.

General Specification:

Application:

Vacuum cleaner, Air conditioning, Exhaust system and ect.

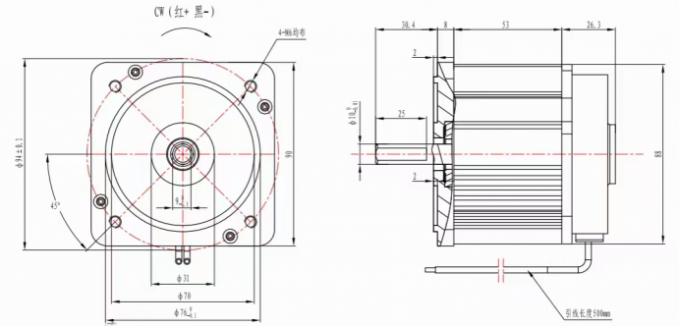

Dimension:

Parameters

| Items | Unit | Model |

| W8520A | ||

| Rated voltage | V | 74(DC) |

| No-load speed | RPM | / |

| No-load current | A | / |

| Rated speed | RPM | 2000 |

| Rated current | A | 2.5 |

| Rated power | W | 120 |

| Rated Torque | Nm | 0.573 |

| Insulating Strength | VAC | 1500 |

| Insulation Class | F | |

| IP Class | IP40 |

FAQ

1. What are your prices?

Our prices are subject to specification depending on technical requirements. We will make offer we clearly understand your working condition and technical requirements.

2.Do you have a minimum order quantity?

Yes, we require all international orders to have an ongoing minimum order quantity. Normally 1000PCS, however we also accept the custom made order with smaller quantity with higher expense.

3.Can you supply the relevant documentation?

Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required.

4.What is the average lead time?

For samples, the lead time is about 14 days. For mass production, the lead time is 30~45 days after receiving the deposit payment. The lead times become effective when (1) we have received your deposit, and (2) we have your final approval for your products. If our lead times do not work with your deadline, please go over your requirements with your sale. In all cases we will try to accommodate your needs. In most cases we are able to do so.

5.What kinds of payment methods do you accept?

You can make the payment to our bank account, Western Union or PayPal: 30% deposit in advance, 70% balance before shipment.